September 13, 2024

A digital response to shipyards’ multifaceted efficiency challenges

What do competitive markets, changing demographics and the energy transition all have in common? They are powerful forces driving a need for greater efficiency in the ship design and building process – which, in turn, is accelerating the digital transformation of the sector.

The market’s tectonic plates are shifting. The headline-grabbing rivalry between the world’s shipbuilding giants, such as China, Korea and Japan, is only the most visible part of fierce competition between individual shipyards and engineering companies.

Shipyards are not only competing for newbuild orders; they are also seeking to position themselves and develop their skillsets in emerging markets for innovative vessels propelled with new fuels and technologies. In this context, players who can reduce delivery times and create better designs, all while maintaining financially healthy businesses, will gain a competitive edge.

Productivity improvements are no longer a “nice-to-have”; they must be at the core of companies’ business strategies. This is a must-win battle to future-proof their activities.

Labor shortages

Whilst competition is fierce, many shipyards and engineering companies, particularly smaller and mid-sized businesses, are fighting with one hand tied behind their backs due to shortages of workers and engineers. Attracting new talents to the shipbuilding industry has been increasingly difficult amid the rapid population decline in Japan and Korea. In Korea, shortages of skilled workers have been particularly acute in the past couple of years, since COVID-19 restrictions were lifted, although the roots of the problem can be traced back to the layoffs that followed a major market downturn a decade ago.

This recruitment challenge comes at a time when yards are seeing increased demand for newbuilds, with some orderbooks full until 2027, and innovation, driven by the needs of the energy transition. Some shipyards are already facing delivery delays as a direct result of staff shortages and an increase in engineering workload. Without action to maximize the productivity of their existing workforce, both in design and construction teams, they will not be able to seize the opportunities of a booming market and may lose market share to their competitors.

Digital technology can help alleviate recruitment challenges on two fronts: by making the sector more attractive to younger generations, and streamlining design processes to enhance productivity.

How data can drive efficiency and support better ship design

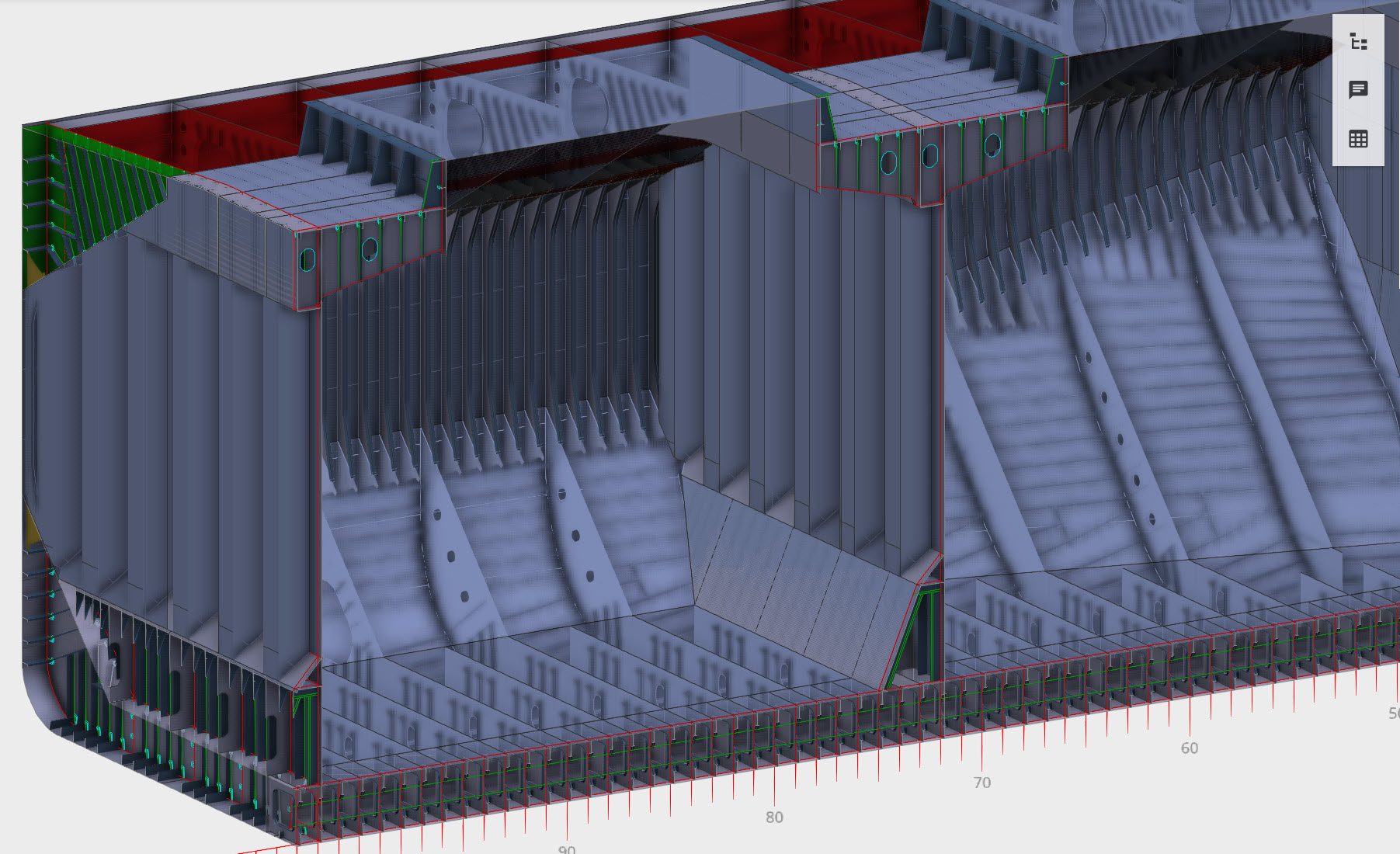

Fundamental (and digital) change is already underway. Shipyards and engineering companies of all sizes and from around the globe are seeking solutions to improve their efficiency. As a result, the use of 3D models is becoming more widespread and integral to the design process, although the level and scale of digital implementation varies from one shipyard to another.

The potential efficiency gains are multifaceted: by enabling the consistent use of 3D models throughout the design process, from early concept stages to detailed design, classification approvals, and all the way through production, we can break silos between disciplines, achieve efficient feedback loops, while also reducing the time spent on data input and conversions, and limiting the risk of errors. Ultimately, reusing the 3D model in downstream production design will provide accurate information to support key decision making, while also saving time from production planning to procurement.

Given the fast-paced innovation that the energy transition needs, digital tools that help streamline processes are also laying the groundwork for more efficient and collaborative workflows that can manage the complexity and engineering challenges of new fuels and technologies.

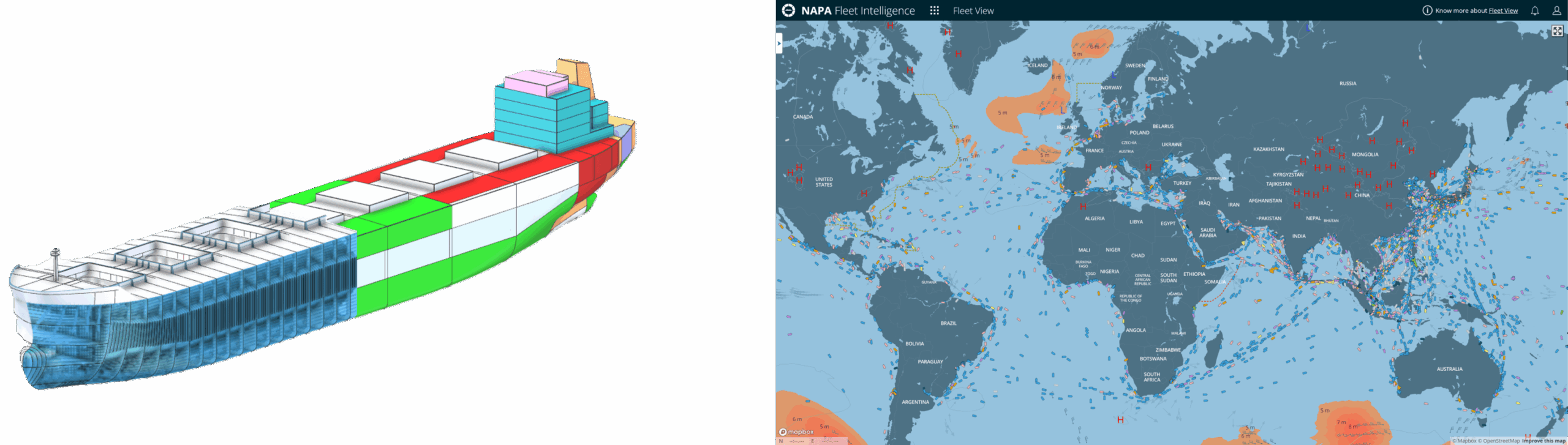

The digital era opens the door to the use of 3D simulation tools, which can model the future ship’s performance from the very early design phase. Assessments such as virtual voyage simulation, alternative fuel comparison, wind-assisted propulsion simulation, and load case simulation are all already helping naval architects and engineers assess different alternatives and make the best possible decisions at a time when businesses cannot rely on previous experience alone.

Alongside the right tools, efficient workflows help ensure that naval architects and engineers can manage increased workloads and complexity by preventing manual data entry and eliminating duplicated tasks, allowing individuals to focus on actual design work. These improvements enable rapid design iterations and flexible change management, contributing towards enhanced productivity and better design decision-making for all stakeholders. In short, these agile processes will prove critical for staying competitive and innovative.

The future of ship design

Companies who seize this opportunity to use digital tools to improve their processes will not only save time and add value to their designs today, but they will also build the right foundations to remain competitive in the markets of the future, where efficiency and innovation will be key differentiators. In other words, embracing digital transformation today can help prepare shipyards for success in an evolving industry.

In the longer term, the ongoing information and technology revolution will unlock a world of opportunity for shipyards, from digital manufacturing to digital twins, that will create new value. This could, for example, enable shipyards to produce a digital replica of their manufacturing facilities to simulate and optimize workflows, production processes, and outputs.

The road ahead is both challenging and exciting. The ongoing technology and energy transformation will define new business models for shipyards. This will disrupt the market’s tectonic plates even further, shaping new areas of expertise, while also opening opportunities to harness technology for smarter shipbuilding.