Bluetech Finland: Leveraging 3D models for superior efficiency in ship design

Bluetech Finland, a ship design and engineering firm, outshines in adapting swiftly to the evolving demands of ship design, ensuring high-quality outcomes for their clients. NAPA’s design solutions, including stability calculations and detailed design capabilities with the advanced 3D model, have been crucial tools for their daily work since the company’s start. These tools play a key role in achieving efficiency, speed, and client satisfaction across projects, positioning Bluetech and NAPA as partners shaping the future of maritime engineering.

Based in Helsinki, Bluetech Finland is at the forefront of maritime engineering, offering a wide range of ship design services. Their team of 80 experts specializes in various types of vessels, including cruise ships, RoPax, cargo ships and de-carbonizing retrofits, covering the design phases from concept to detail design. Collaborating with some of the world’s leading shipyards, Bluetech Finland delivers diverse solutions to the maritime industry, spanning design and consultancy.

Flexibility, an essential in the design process

Designing a ship is a process of iteration. The ship design process involves a series of ongoing revisions, where frequent modifications and fine-tuning are integral to finalizing the ship design for production.

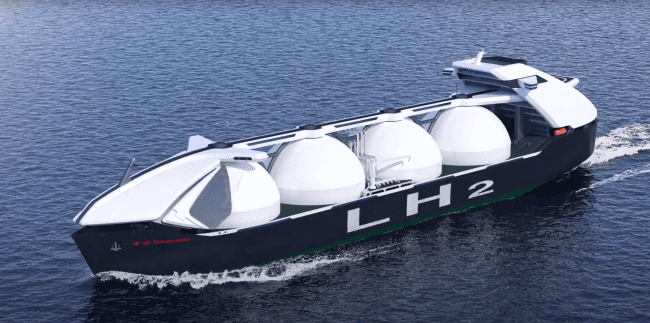

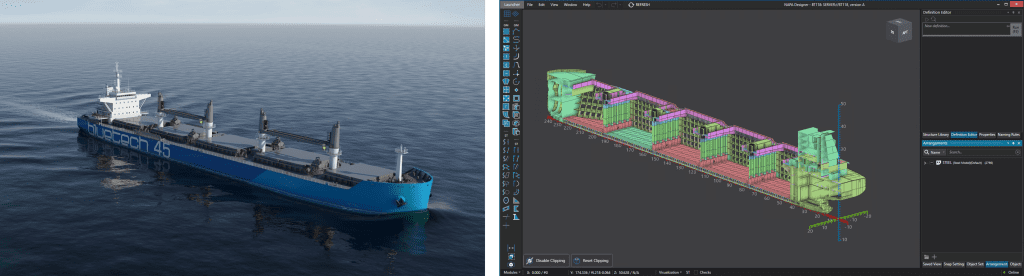

Bulk Carrier concept design by Bluetech Finland

Adapting the changes and analyzing the updated design to meet customer requirements is a common practice in the ship design field. – Mikko Hakulinen, Head of Hull Basic Design at Bluetech Finland

Particularly in the early ship design phase, creating and updating finite element (FE) models is crucial for speed and adaptability in the design process, made possible by the rapid development of the ship’s final 3D model. Mr. Hakulinen highlights that “NAPA solutions have enhanced our ship design process through their efficiency and flexibility, enabling rapid changes and the early creation of 3D models, which are key to streamlining design workflow.”

Concept model of a methanol-ready cargo vessel designed by Bluetech Finland

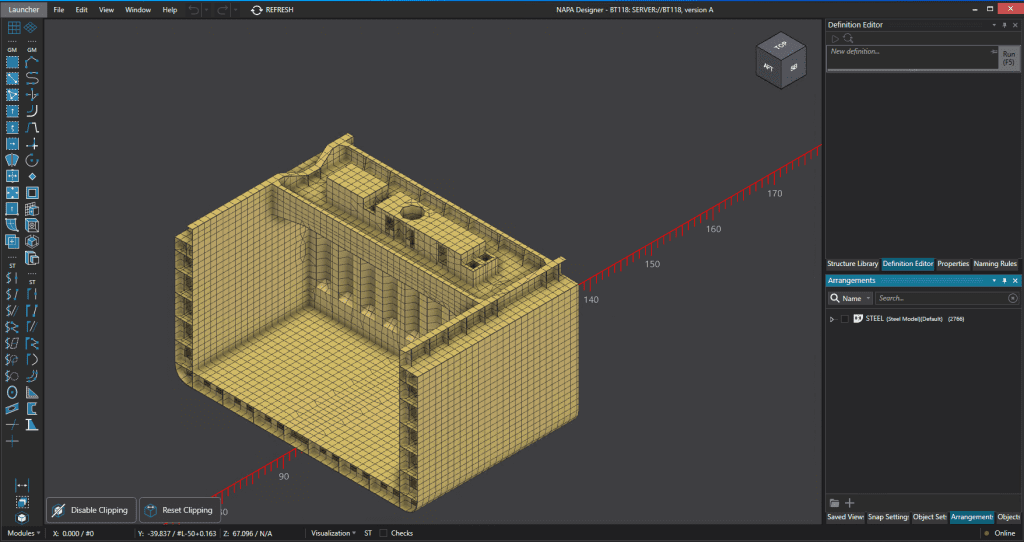

Global mesh created with NAPA tools as a part of the concept model of a methanol-ready cargo vessel

In addition, ensuring timely and open communication with all stakeholders within the ship design process is vital, as there is always a high demand for the prompt sharing of updates and discussions on design modifications. NAPA notably improves this process by facilitating quick and efficient design changes through a single 3D model, thereby enhancing the way of communication of the entire design work process.

Streamlining the ship design process for all stakeholders

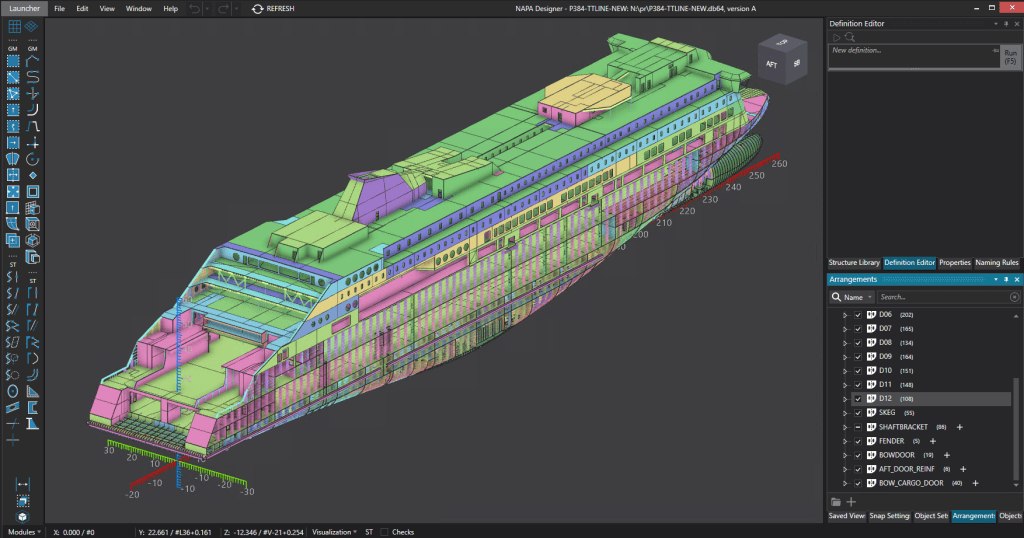

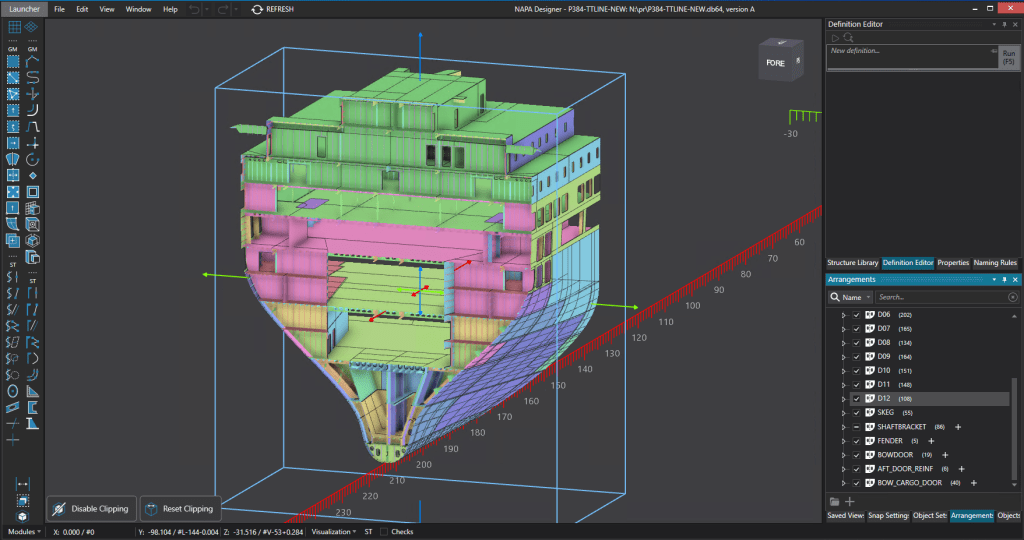

These benefits were particularly evident in the recent TT-line Spirit of Tasmania ferry project, where Bluetech Finland played a key role in the technical and detail phase of hull structure design. Bluetech Finland developed a structural 3D model using NAPA Steel at the early stages of the project, ensuring consistent data storage. NAPA 3D model acted as a central reference point, enabling collaboration across all disciplines involved in the project, thereby streamlining the ship design and building process.

Concept of the Spirit of Tasmania by Rauma Marine Constructions Oy

The transition from technical design to production design typically has major challenges due to technical issues and design schedules. Technical reasons include typical late changes in the technical design, for example, incorporating late changes to production design or the FEA (finite element analysis), pose resource and timing challenges. NAPA Steel offers a solution by enabling swift, major changes and efficient integration with production design, streamlining the transition and mitigating potential delays.

The seamless integration of the NAPA Steel model over to the production design model significantly eases the challenge with the design schedule. Quickly transferring the functional model to the production model brings significant advantages. Once the model is accessible in the production environment and visible to all related design disciplines, it notably accelerates the initiation of detail design work. Typically, the method to tackle these time scheduling challenges leads organizations to start the detail design a bit prematurely earlier than ideal. That contains major risks if there are substantial changes in the design at a late stage. Also, this early start can lead to data loss along with the time-consuming traditional design transition process.

3D model of the Spirit of Tasmania in NAPA Designer

NAPA’s compatibility with other CAD software offers a significant advantage by allowing the use of a single NAPA 3D model throughout the ship design process. This enables testing multiple design variations within the same model and facilitates rapid iterations, including frequent FEM analyses.

This approach not only streamlines the transition to detailed design but also enhances design quality and ensures consistency in information management. – Mikko Takala, Project Manager at Bluetech Finland

During the design of Icon of the Seas, the world’s largest cruise ship, NAPA’s 3D model played a pivotal role in enhancing design accuracy. Bluetech Finland supported Meyer Turku shipyard in developing the ship’s foundational structure using NAPA Steel. To meet the needs of the client, Bluetech Finland utilized NAPA’s tools to assess technological use and cost implications from a series of model updates. NAPA design solutions were instrumental in providing vital information for efficient project management.

One of the key benefits of NAPA design solutions is ‘Listing’. While various software options exist for ship design and 3D modeling, NAPA stands out for its effectiveness in reporting the design development in numbers, such as generating essential reports and documentation all the way to the final delivery.

says Antti Metsä, Director, Administration at Bluetech Finland, who brings an extensive background with over 36 years of experience using NAPA software, showcasing his deep expertise in the field.

Enhanced solutions for tomorrow’s needs

Considering escalating environmental challenges, the maritime sector’s push towards sustainability and net-zero goals will lead to significantly different future ship designs. Mr. Takala explains that “Using the most adaptable and efficient design tools is inevitable to accommodate the unique design characteristics for the future ship. Emerging vessel technologies like wind-assisted propulsion, alternative fuels, and energy efficiency improvements call for designs with specific weight, volume, and shape considerations. We aim to deliver perfectly tailored designs for each vessel type, ensuring they meet the highest standards of performance and eco-friendliness.” Bluetech Finland aims to leverage NAPA’s versatile solutions to maintain a competitive edge in designing these innovative vessels.