December 13, 2021

DORIS Engineering uses NAPA’s flexibility and speed to overhaul its operations

An offshore design specialist DORIS Engineering SAS uses NAPA software to accelerate its design processes and deliver competitive options for customers

DORIS Engineering

DORIS Engineering offers high-quality engineering to the oil and gas, and renewable energy markets. It provides performance- and cost-driven solutions, from concept to decommissioning, and includes all the engineering services that energy operators and contractors need to enable safer, faster, and lower-cost production.

DORIS has used NAPA since 2015. It has previously and continues to use, various modules for design, stability and hydrodynamic analyses, finite-element modeling and general arrangement planning.

Background

Any fixed or floating structure for the offshore energy market, such as FPSOs, FSOs and FLNGs, inevitably contain a complex combination of structural integrity and operational efficiency. DORIS Engineering has a large design team focused on achieving those objectives both cost-effectively and on a strict timetable. NAPA’s processes enable thousands of iterations to refine initial ideas into optimum solutions in a time-efficient manner for its customers.

In the six years that DORIS Engineering has been using NAPA, it has become an essential and reliable tool across its naval architecture department. In close coordination with its engineering teams, DORIS Engineering develops major CAPEX and OPEX optimizations, significantly reducing technical, interface and planning risks for their customers’ projects. While DORIS Engineering has had the experience of a number of software systems for various functions, NAPA is still its go-to choice for design and analysis activities.

Challenge

One of the main focuses of DORIS’s portfolio is the upstream oil and gas sector, with the majority of its work involving naval architecture design for floating structures, like FPSOs, FSOs and FLNGs. Fixed structures may also require naval architecture considerations for their installation phases.

While these structures may appear to be simply large floating boxes, their complex oil and gas treatment facilities and storage requirements impose strict limitations on their structural integrity, stability afloat and hydrodynamic behavior.

These present challenges to DORIS’s design team that its previous software failed to fully address. For example, the stability calculations in the previous software used by DORIS were very basic, so for projects that involved many loading conditions, considerable amounts of further analysis were required on its outputs to develop all the necessary information. It could not provide reliable stability results, for example.

There were even occasions when the previous program’s output was clearly incorrect, possibly because it found the shapes used in offshore structures were incompatible with its inflexible algorithms.

NAPA Solution

Since 2015, DORIS has used a growing number of NAPA software modules. These modules have helped it overcome the difficulties it previously faced with less sophisticated software. The company’s first experience with NAPA’s capabilities was on a project for Total Energies that involved modifications to an FPSO operating in Angola. DORIS had been contracted to carry out stability checks on the amended vessel. A senior DORIS naval architect had experience using NAPA in a previous role and recommended that a license be bought.

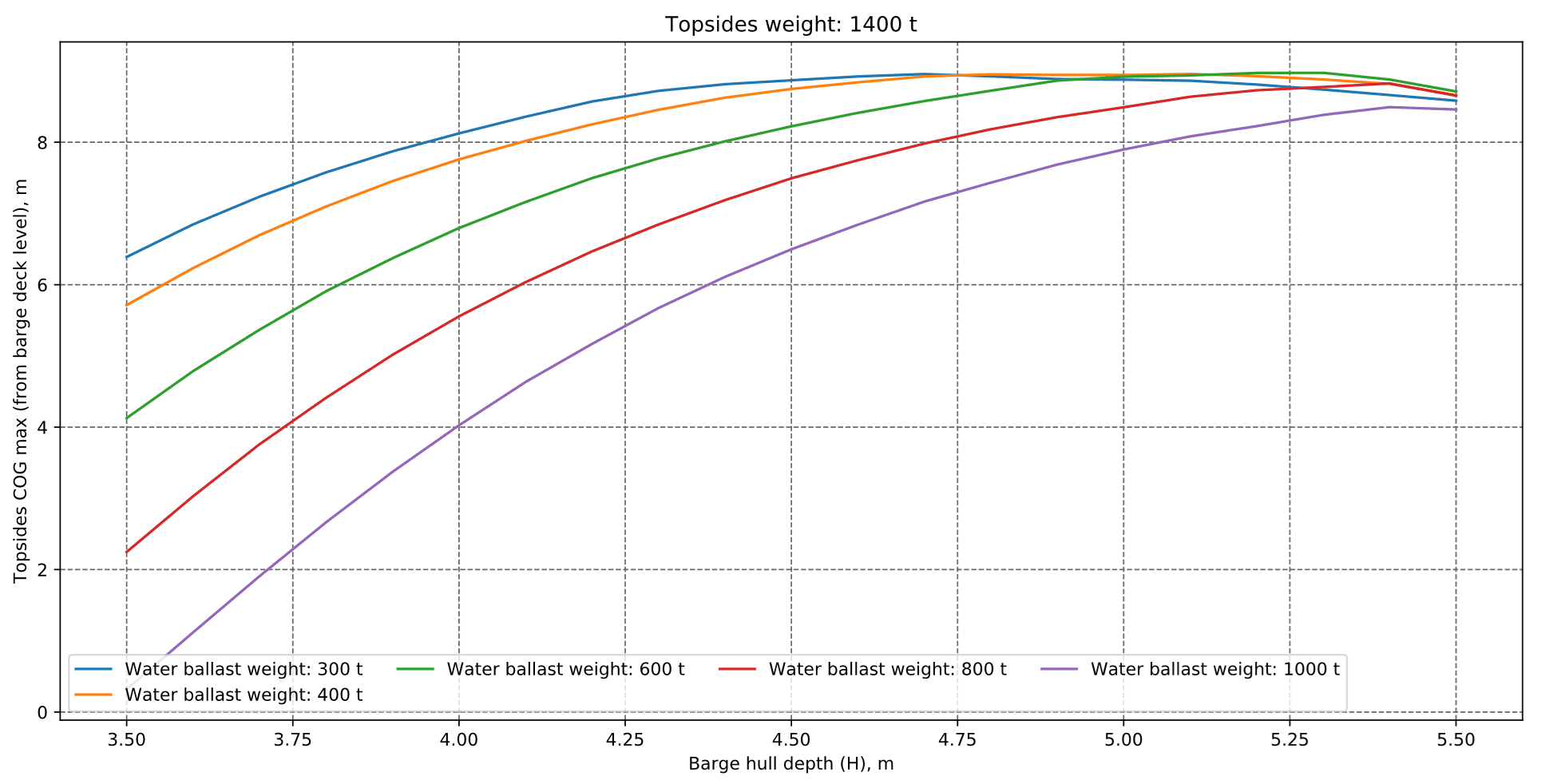

Since then, DORIS has expanded its use of NAPA modules. For example, a particular challenge when designing floating production plants is to keep the unit center of gravity within the envelope where the stability criteria are respected. This envelope should be well defined in the early project stages.

To achieve this on an installation project in Kazakhstan, DORIS Engineering used NAPA to analyze a large number of the center of gravity positions, where for each of them it used NAPA’s balancing function. Furthermore, a complete stability verification was performed and the critical KG value was found. Based on this data the COG envelope curves were able to be traced.

DORIS’s naval architects used this to perform the analysis for both intact and damaged conditions, which provided clear information for the topside equipment design team on where they could locate their equipment. This was updated during the project because the hull’s weight changed slightly during the project.

NAPA software is built around a set of core principles that have been in place since it was founded more than 40 years ago. One of its primary principles is giving users the flexibility needed to perform advanced, efficient and accurate calculations. One DORIS designer said that its capabilities are limited only by his own imagination. He compared it to a set of LEGO bricks: once a designer has learned how they fit together, “you can build whatever you want.”

If needed for particular applications, NAPA can also supply ‘bricks’ to link its program to other design systems; DORIS has made use of this capability for a project to design a support for a Floating Offshore Wind Turbine (FOWT). For example, NAPA’s consultants wrote a .NET plugin that allowed the other program to be started from within, and for the output from the other program to be delivered back to the NAPA system to be used for the genetic algorithm optimization routine.

Finally, the most important benefit of using NAPA is the time it saves, compared with other design systems, DORIS reports. A design can be completed in a couple of weeks – including a complete stability analysis – which is about half the time required when compared to other software. This has an impact on the number of design options that can be explored and on a project’s cost, both contributing to a more competitive quote to the customer.

Conclusion

Using NAPA’s modular design suite has enabled DORIS Engineering to conduct more and better design analyses and has given it the flexibility to develop novel floating structures, both in the O&G industry like FPSOs, FSOs and FLNGs, and in the renewables industry like a Floating Offshore Wind Turbine (FOWT).

Compared to design other options, NAPA software enables faster performance and reduces design time. This allows for more detailed and competitive quotes to be presented to customers.