November 15, 2024

Vard Marine – mastering complexity to design innovative ships

“Tailor-made” is the watchword at Vard Marine, a naval architecture and marine engineering firm that prides itself on creating highly specialized vessels customized to each owner’s needs. But delivering novel concepts every time is no mean feat – its designers need the right tools to manage iterations efficiently and evaluate the viability of concepts early. They’ve got an ally in NAPA.

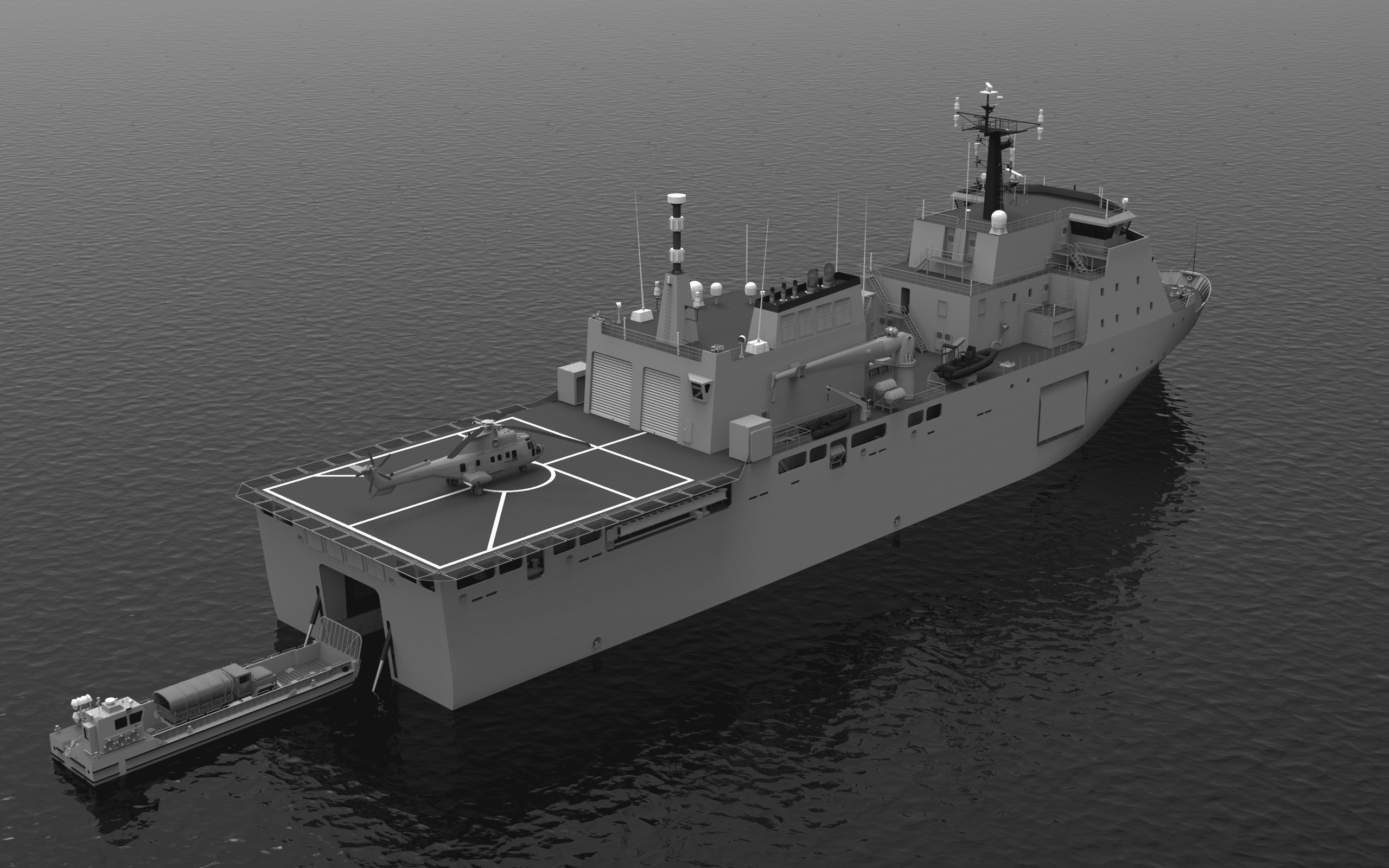

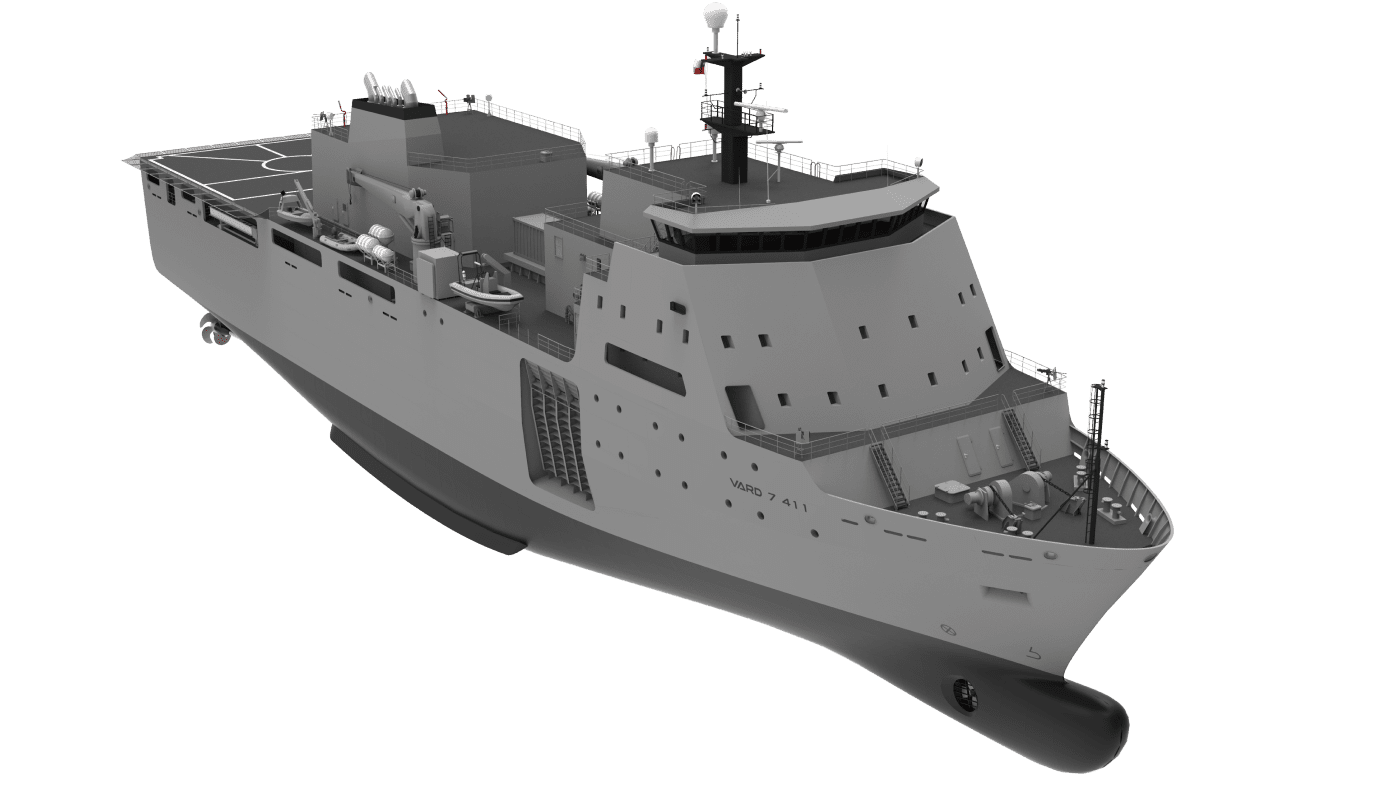

With offices in Canada, the United States, Vietnam and Poland, Vard Marine’s core business revolves primarily around specialized vessels, including icebreakers, offshore and renewable vessels, as well as ferries, research, patrol and alternative fuel bunker vessels. While it specializes in concept to basic design, the company also regularly collaborates with shipyards on detail and production design.

Vard Marine’s goal is to be the designer of choice for client-tailored, specialized vessels. To achieve this, its teams take customization to new heights, carefully optimizing each design for the owner’s unique needs and operations. “We really want to make sure that our clients get not only the ship that they need but also the best possible ship that we can deliver,” said Denley Rumbolt, project naval architect and lead NAPA user at Vard Marine.

Making this vision a reality required innovation in the design process itself. “Previously, progress in particular areas of ship design was limited by some of our design tools,” Mr. Rumbolt remarked. Instead, the company needed tools that would give its engineers more flexibility to manage the multiple iterations that are inevitable with novel designs, as well as the ability to validate the feasibility of concepts earlier in the process. Enter NAPA’s ship design tools in 2019, which helped transform workflows on both fronts.

Leveraging stability as a design tool

Central to Vard Marine’s ability to create novel and tailor-made designs is the use of NAPA’s stability calculations as a tool to inform ship design from the early stages, rather than a compliance check done at various stages in the process.

Stability has always been assessed as early as technically possible at Vard Marine. However, some software limitations previously reduced the process to simply checking stability for regulatory compliance when changes occurred in the vessel design process, which was more often than was desired.

There was a desire to use stability as a tool to inform the design process, rather than be reduced to a compliance check, especially for blank-sheet novel designs. NAPA empowers this design philosophy.

– Denley Rumbolt, Project Naval Architect, Vard Marine Inc.

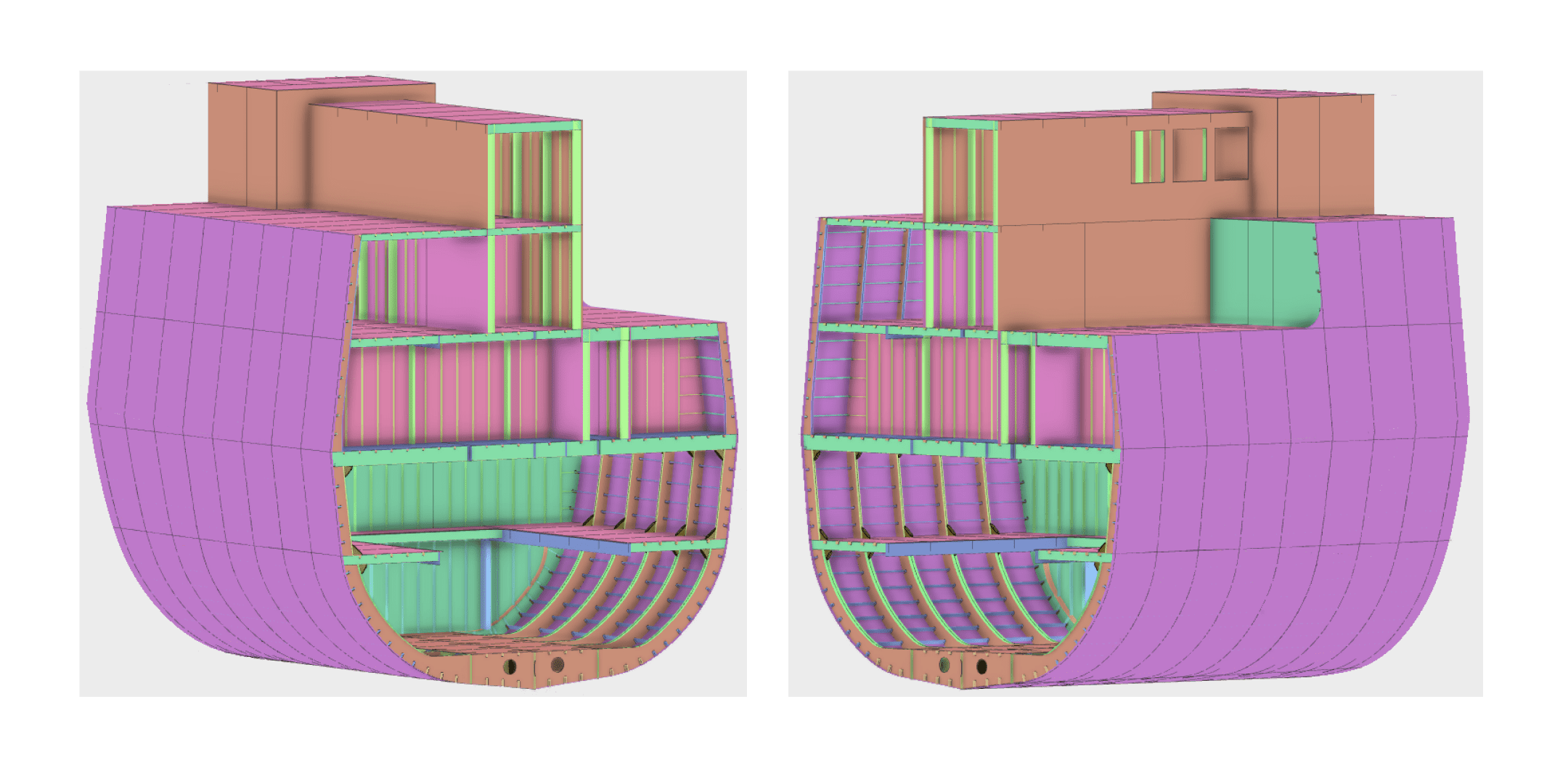

NAPA tools solved this issue. They enable Vard Marine to perform stability calculations from the outset and leverage them as a design tool. In practice, as soon as a rough hull form is created, it is inputted into NAPA software to establish “limits” for each compartment. In other words, stability teams can determine acceptable “envelopes” for variations in weights, beams, lengths and centers of gravity that can be tolerated, to ensure that the final ship will meet stability requirements. Those envelopes are then communicated with the other disciplines, including mechanical, arrangement and weight estimation teams, giving them clear boundaries within which they can work and innovate with confidence.

Knowledge is power

This was a game-changer. NAPA can be used to quickly and easily develop a clear picture of the areas where unprotected openings can be added without impacting the ship’s stability, so mechanical teams can start work earlier on positioning tank vents, piping or HVAC. “They really bought into this idea because it gives them guidance on the margins within which they are free to work. And if they can’t meet those limits, we can single out those instances and find solutions,” Mr. Rumbolt added.

Using stability as a design tool also brings another key advantage: the ability to quickly assess if changes are feasible. For example, in recent design work, the arrangements and hydrodynamics teams needed to know if the vessel’s beam could be slightly reduced, which would enable them to size down the engine and auxiliaries. For the owner, the difference is massive in terms of capital costs and fuel savings throughout the vessel’s lifetime.

“Using NAPA as a design tool allows us to provide information to the rest of the design team that we wouldn’t have been able to do as easily before using NAPA. Because we can more easily look at limits earlier in the process, we are able to get ahead of potential problems and, therefore, reduce a lot of re-work, especially in the conceptual stage when the design is a lot more fluid. Of course, that makes us a lot more efficient,” Mr. Rumbolt highlighted.

Managing design iterations

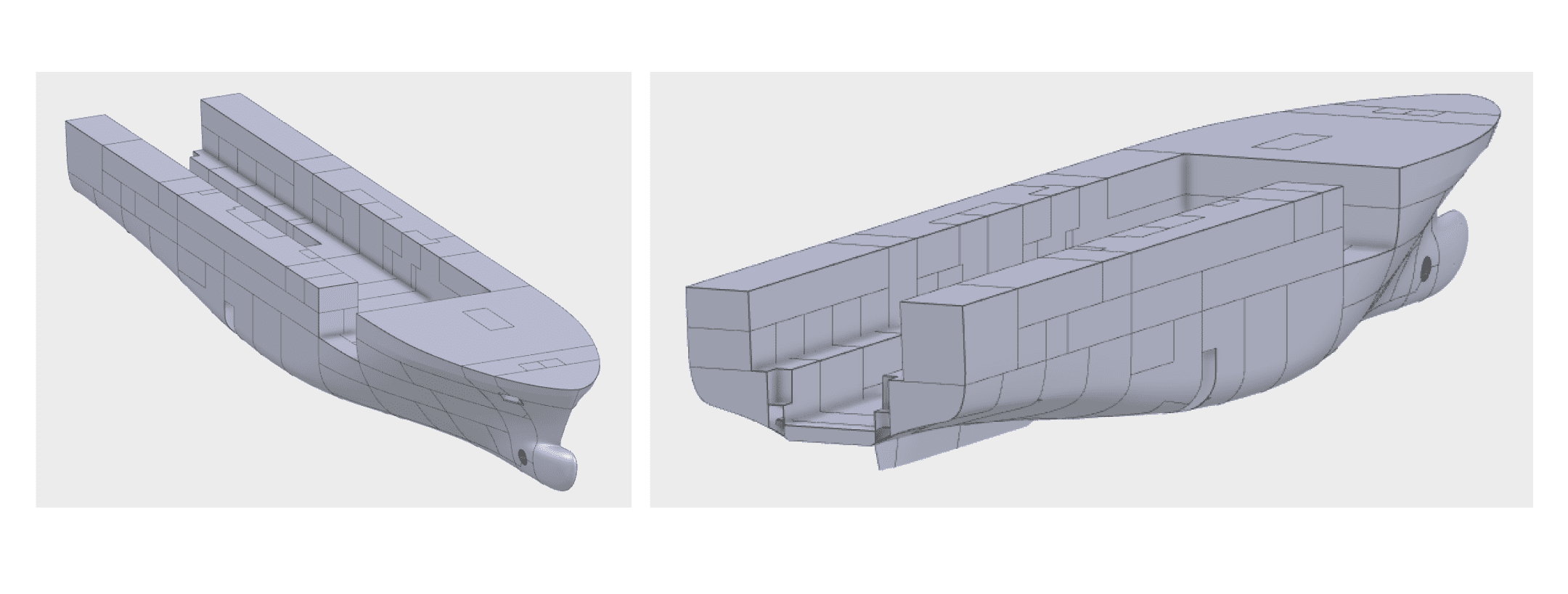

Another prerequisite for innovation is the ability to manage the multiple iterations that are inevitable with novel concepts. This is where NAPA’s parametric design capabilities came into play. By setting up a parametric model from the beginning of the process, teams can easily iterate the model and test different design options. Put simply, when one parameter is changed, the other geometries are automatically adapted. This can be used not only for the ship’s main characteristics and hull forms but also, at a more granular level, for the internal arrangements.

This was instrumental in the success of a concept for the US offshore wind market. It enabled Vard Marine designers to find the right balance between competing variables to determine the optimal metacentric height (GM) to maximize seakeeping while ensuring that stability criteria were met. Teams were able to trial several iterations of subdivision arrangements to create a vessel that was not only compliant, but had the largest possible operability envelope to meet the client’s needs.

Constant innovation

These efficient and agile design processes help Vard Marine build solid foundations for the era of fast-paced innovation ahead. Already a core consideration for the shipping industry, decarbonization will grow in importance, calling for new energy sources to power vessels.

This will bring new complexities and challenges for designers, and the capacity to innovate will be key. Because new fuels are less energy-dense than their fossil counterparts, the ability to improve hydrodynamics and hull form designs to make ships more energy-efficient will be a big advantage going forward, Mr. Rumbolt noted.

Vard Marine is embracing this future with the confidence that it has laid solid foundations for innovation. Equipped with NAPA’s tools, their teams can manage complexity and focus on what they do best: creating novel vessels for a rapidly evolving industry.