Digital Permit To Work System: Game-changer in Enhancing Crew Safety and Efficiency

Traditional paper-based workflows are no longer sufficient in the modern maritime industry. These old-school processes are prone to errors, delays, and miscommunication, compromising crew safety and operational efficiency.

The industry has made big improvements in seafarer safety over the past decade. However, accidents still happen when crews are at work. Recent IMO statistics from InterManager reveal that in the last 28 years, 55% of onboard accidents occurred during planned shipboard work, with most taking place in the hold, access areas, and oil tanks.

A digital permit-to-work (PtW) system helps you abandon outdated, paper-heavy procedures to make your shipping operations more efficient and safer. With it, you can provide seafarers with step-by-step dynamic guidance when handling hazardous tasks. This reduces the chances of errors and missed steps.

Whether your safety teams are onboard or onshore, an electronic permit-to-work system gives them real-time visibility into the work that is happening on the ship. With this enhanced oversight, you minimize the likelihood of overlooking critical issues that could put seafarers at risk, especially those new to the job.

What are Permits to Work and why digitalize them?

A permit to work is a legally required process for authorizing hazardous tasks on board and ensuring they are performed safely. The potentially dangerous activities on a ship may include working at heights, carrying out flame or spark-producing operations, and entering enclosed spaces.

Traditionally, shipowners and operators manage this process through paper forms as part of their safety management. That means crew members waste a lot of time walking around the ship to get the necessary signatures before obtaining the authorization to perform high-risk tasks. Manual processes in traditional permits increase the risk of mistakes, delays, and miscommunication, creating safety hazards for workers.

With a digitalized permit-to-work system like NAPA, you use electronic forms and digital permits to overcome the challenges of paper-based processes. For instance, Virgin Voyages uses NAPA’s permit-to-work system to eliminate manual work permit procedures like signature collection, avoid wasting time on paperwork, and improve data accuracy.

Carnival Cruise Line sails with NAPA Permit to Work

Advantages of Digital Permits for Seafarers

Here’s how electronic permits benefit your shipboard crew.

Save Time and Simplify Processes

Crew members can easily and quickly obtain approval through a digital permit-to-work system. Once someone completes the necessary safety checks and fills in all the required details on a digital form, they can ask for permission to take on a task at the press of a button. The relevant team leaders can instantly review and approve the request.

In other words, digital automation in Permit to Work software eliminates the need for manual signature collection, reducing administrative burden.

Minimize Error and Enhance Safety of Workers

A digital permit is a comprehensive checklist for seafarers to ensure they don’t miss any operational safety measures or steps. Additionally, electronic permit-to-work systems ensure a digital form is only accepted when all relevant details are accurate, and every safety requirement is met before the start of any job.

With robust Permit to Work software, you can create a more secure working environment, even if you operate numerous ships. As a company with one of the largest fleets in the world, Carnival Cruise Line trailed the NAPA’s permit-to-work system to support seafarer safety and make operations more efficient.

Pievalerio Vignola, Director FOC, Carnival Cruise Line, says, “Crew safety and welfare are key pillars for our operational and commercial success, which is why investing in our continued digitalization with NAPA was a no-brainer. Embracing these digital technologies gives us the peace of mind that we uphold rigorous safety standards protecting our crew, passengers, and assets.”

This level of safety keeps seafarers out of harm’s way and helps organizations comply with crew protection regulations.

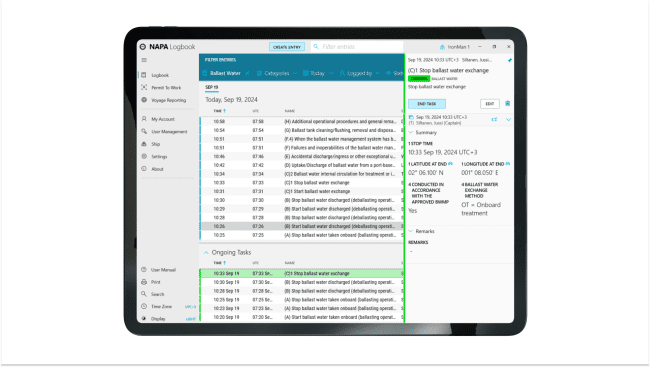

Reduce Paperwork and Provide Real Time Updates

In the traditional permit to work process, seafarers often print and carry an approved work permit. However, this approach is ineffective when a task’s status change every few minutes. For example, working in enclosed tanks, crew may need to measure gas concentration after every 30 minutes. When you digitize the process, your team can access a live work status. That means team leaders on the can get easy and real-time status update from anywhere in the ship.

Virgin Voyages sails with NAPA Permit to Work

Advantages of Digital Permits for Shoreside Teams

Ship owners, operators, and safety teams that work on land to support maritime operations can enjoy the following benefits of an electronic permit system:

- Get fleet-wide visibility: A shoreside team that manages multiple ships can seamlessly track ongoing work across the entire fleet in one platform.

- Stay on top of matters: Even if you’re not on board, a digital Permit to Work system gives you live updates of what’s happening on the ship. This real-time awareness keeps you ahead of delays or technical issues for a proactive approach to safety.

- Improve maintenance management: Digital Permit-to-Work software can gather and analyze data for each ship, every voyage, every leg. You can use the resulting insights to evaluate which machines on your vessel need maintenance and take action early.

Looking Ahead: A Necessity Born From the Complexity of Onboard Work

As new fuels and technologies transform the maritime industry, onboard work will become increasingly complex.

As shipowners and operators deploy new technology and innovations, you must be aware of their safety challenges. Knut Ørbeck-Nilssen from DNV Maritime has sounded the alarm, saying there’s a growing “safety gap” between the current work practices and the rapid adoption of new eco-friendly technologies in ships.

DNV’s 2024 Maritime Forecast Report further mentions, “While decarbonization is the dominant transforming driver in shipping, maintaining an acceptable safety level is a prerequisite when introducing new technologies and solutions. Additionally, new fuels introduce novel safety risks, requiring new design solutions and large-scale training of seafarers.”

Recognizing this growing challenge, NAPA is working hard to close the “safety gap” by providing a digital tool that simplifies onboard operations. This makes everyday tasks more manageable, and enhances crew protection.

To streamline operations in their vessels, ship owners and operators will need a suite of digital tools, including automated permit-to-work, checklists and electronic logbooks. These solutions promote crew efficiency, ease reporting and regulatory compliance. NAPA’s solutions can help you achieve measurable results. For example, Anthony Veder is a leader in the tanker shipping sector with over 20 vessels. According to the company’s 2023 sustainable growth report, it reduced administrative workload by 14% and saved 2000 hours per vessel after implementing an electronic logbook from NAPA.

Unlocking the Potential of Data for Ship Operations

When the phrase “ship operations” pops up, the typical things that come to mind are route optimization, weather conditions, fuel efficiency, and operational safety excellence. After all, they are some of the most business-critical factors to consider.

However, there’s so much more to ship operations than just these elements. Research shows that about 90% of data generated on a ship never leaves the deck. Tapping into this data could mean getting valuable insights to boost performance and efficiency.

When you digitally track analytics related to safety, engine management, HVAC, waste management, and even food consumed on your cruise ship, you can better measure, report, and monitor your environmental impact. With a sturdy digital system, you can easily manage all your ship data in a single central platform.

NAPA’s Mission: Harnessing Untapped Data Through Digitalization

NAPA aims to help ship operators take advantage of untapped data by digitizing as many processes as possible. That way, companies can automatically collect information about their onboard operations and use the insights to make data-driven decisions that improve workplace safety.

Long before NAPA’s permit-to-work system launch, we’ve been focusing on transforming how organizations in the maritime sector obtain and access insights about their ships. Our fundamental goal has been to put everyone on the same page — onboard or onshore.

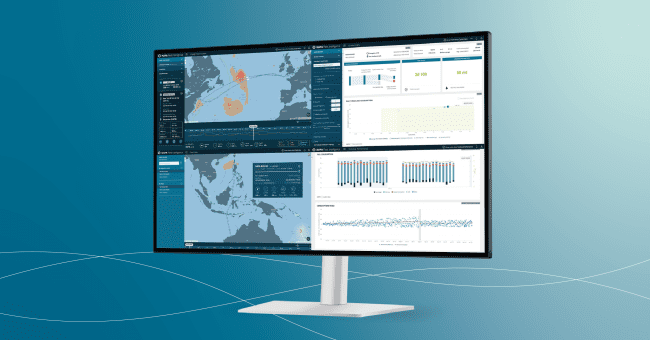

That’s why instead of simply enabling companies to gather valuable information in a single, central platform, we help them make it available to shoreside teams through cloud-based software technology.

Learn More About NAPA’s Digital Permit to Work System

Find out more. NAPA can help you replace time-consuming paper forms in your Permit to Work process by digitalizing work permits and approvals.

Our fully integrated permit system works seamlessly with other NAPA technologies, such as NAPA Logbook, and NAPA Fleet Intelligence.

Learn more about NAPA’s digital permit-to-work system or talk to our experts for a free demo.

Digitalized work permits and approval for safer, faster and smoother operations

To know how NAPA Permit to Work can support your fleet operations, talk to a NAPA expert.

Talk to an expert