Is your cruise ship’s stability data going to waste?

A ship’s stability is no longer restricted to the loading computer. From digital twins to cloud technology and the growing role of shoreside, stability management has taken a massive digital leap.

by Tuomas Häkkinen, Naval Architect and Safety Service Manager

Cruise ships are the safest commercial ships sailing – the safety margins factored into their design and the regulations that govern their operation reflect the most important “cargo” they carry — people. As such, vessels must demonstrate compliance with strict stability criteria needed to operate – for example, showing that a vessel has the right ‘stability reserve’ (safety margin) before it leaves port.

Here, NAPA’s stability and loading calculation solutions play a central role. The data and analytics provided by our solutions are at the heart of all the decisions related to vessel stability management. They are integrated with a 3D model of the ship, a digital twin, based on data and models used during the ship design process. This is a powerful combination, which enables crew and shoreside teams to work together effectively to maintain the highest possible safety standards.

First port of call is always safety

When thousands of passengers trust you with their safety, it isn’t just a priority but a core value for the cruise industry. And NAPA’s stability solutions are critical to ship safety and compliance, for both teams on board and ashore. NAPA Stability covers a wide range of calculations related to hydrostatics, intact stability, damage stability and longitudinal strength, and a unique 3D model with all the relevant naval architectural calculations available in a single package. Added to this are comprehensive flooding analysis functions, such as the ship damage function. Considering, foundered (sunk) was the main cause of total losses across all vessel types during 2021, accounting for around 60%, this analysis can be vital in case of emergencies.

With real-time access to data such as the vessel’s ‘GM curve’ (showing metacentric height), NAPA helps ensure that vessels can easily prove that they meet IMO and SOLAS criteria . This is useful for proving compliance with stability criteria needed to operate – for example, showing that a vessel has the right ‘stability reserve’ (safety margin) before it leaves port.

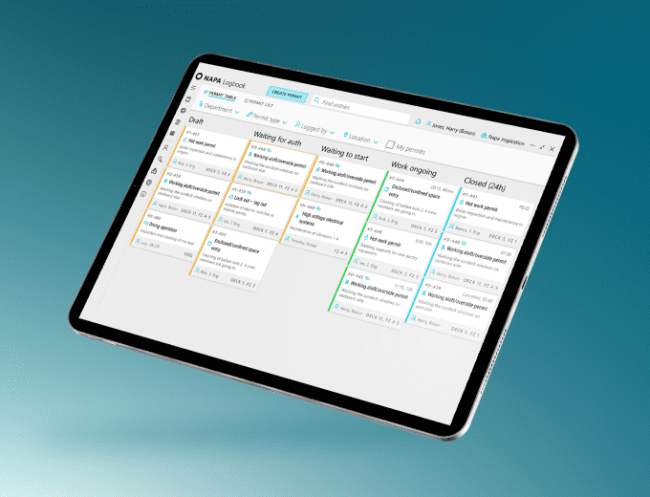

Checking regulatory boxes isn’t nearly enough. Onboard decisions make the real difference. And thus, captains remain the ultimate decision-makers, as only they have a complete shipboard view of what is happening. That said, in order to save time, reduce errors, and prepare for every eventuality, shoreside teams are becoming more and more essential. NAPA has been working hard to make its data and analysis readily available to them. For instance, one of NAPA’s recent projects has been to make loading instruments cloud-based and available online in the NAPA Fleet Intelligence cloud platform. This reduces the need to use specific computers to perform calculations or to separately email data for processing, leveling up the responsiveness and flexibility of shoreside teams. Critically, emergency response teams and shoreside teams can use these digital models in event of accident, or if a quick safety decision is needed, to accurately simulate different scenarios.

Safety and sustainability go hand in hand

While it is easy to see the value of stability data to vessel safety and compliance, it is also critical to vessel efficiency. NAPA Stability can be used to ensure the safe and optimal planning of stowage, cargo and ballast to optimize the ship’s trim, thereby reducing fuel consumption.

Stability data from the NAPA 3D model, managed in the cloud, can also provide shoreside teams with a wealth of information that will ensure that they are operating vessels efficiently. For instance, stability data can help determine whether a ship is carrying unnecessary deadweight by having enough/too much fuel, freshwater, or ballast water. Patterns can emerge over time, and the performance of sister ships can be compared.

Moreover, cruise ships tend to become heavier over their lifetime, as new coats of paint are added, as well as new equipment or refurbishments. Shoreside teams can also use NAPA tools to analyze how a vessel’s stability profile changes over time.

Testing safety with a digital twin first

You’ve ensured safety onboard with the latest technology, regulatory measures and highly trained people. But what if you could predict a vessel’s safety status before it even sailed? The NAPA 3D model and digital twin are key to understanding and communicating the risks, and they remain an important asset beyond the initial design and emergency preparedness.

NAPA has been operating as an integral part of many cruise fleets for several years. Our experts are trusted advisors and are frequently consulted on key stability decisions being made by owners, yards and class. Particularly because so many Naparians are naval architects, we are often called on to advise on newbuild or retrofit projects to help assess stability risks. We can inform on refurbishments, for example, where adding new cabins might change a vessel’s stability reserve to the extent that it can’t operate in challenging sea states or in low salinity locations such as the Baltic Sea. A 3D model and digital twin of the ship, therefore, become a lifetime asset that can help improve safety without taking any risks.

Twin into the future

Considering all this potential, we see the ship of the future as not just the ship itself but also its digital twin. This digital twin enables a multitude of digital scenarios to be tested virtually to make the best possible decisions for the actual vessel.

It’s time to ask: is your ship’s stability data going to waste?

NAPA is here to help you answer that question. We are part of the team, a lifecycle partner in managing stability throughout a vessel’s operations and discovering its full potential for optimizing those operations.