October 25, 2024

Want to design better, greener ships? Operational data can help.

Simulation tools are well-known as the foundation for voyage optimization and advanced stability software that boosts operational safety and sustainability at sea. Now, a new role is emerging for this digital arsenal: powering innovation in ship design, by enabling novel concepts to be tested virtually from the drawing board.

We are at the onset of a multi-fuel and multi-energy era for shipping, which will increasingly be synonymous with personalized designs. Different fuel and technology options will be best suited for specific vessel types and segments, and the most appropriate solution will also depend on the ship’s operational profile and the routes it will navigate.

For example, the recent uptake of battery technology by tugs and ferries shows that those systems are particularly well-suited to smaller vessels on fixed short-sea routes. Wind propulsion systems, on the other hand, will most benefit ships on trans-oceanic routes with strong and reliable winds. The ability to bunker at the different ports where they call will also influence decisions around alternative fuels such as LNG, methanol or ammonia.

But this barely scratches the surface of the multitude of decisions that must be made at the design stage, by engineers and naval architects in charge of developing these novel concepts. The challenge lies not only in integrating new engines, tanks and technologies, but also in selecting the right configurations, dimensions, carrying capacities, strength and hull form to ensure that those designs will be viable once at sea – from a safety, efficiency, and profitability perspective.

The ultimate goal would be to enable ship designers to model, from the very early design stages, how a new vessel concept would perform once commissioned. In an ideal world, they want to be able to do this swiftly and easily, so they can test different iterations and truly optimize their concepts.

Traditionally, designers would make those assessments based on data from similar vessels, but this data is often incomplete or based on simplified rules that have, on average, worked well in the past. This approach may no longer reflect the best approach for the vessel design and can stifle innovation. Plus, what about completely new designs where past data does not exist? The answer lies in tools that are already widely used in shipping operations, and re-purposing them to extract new insights for ship design.

Three steps to simulate future performance

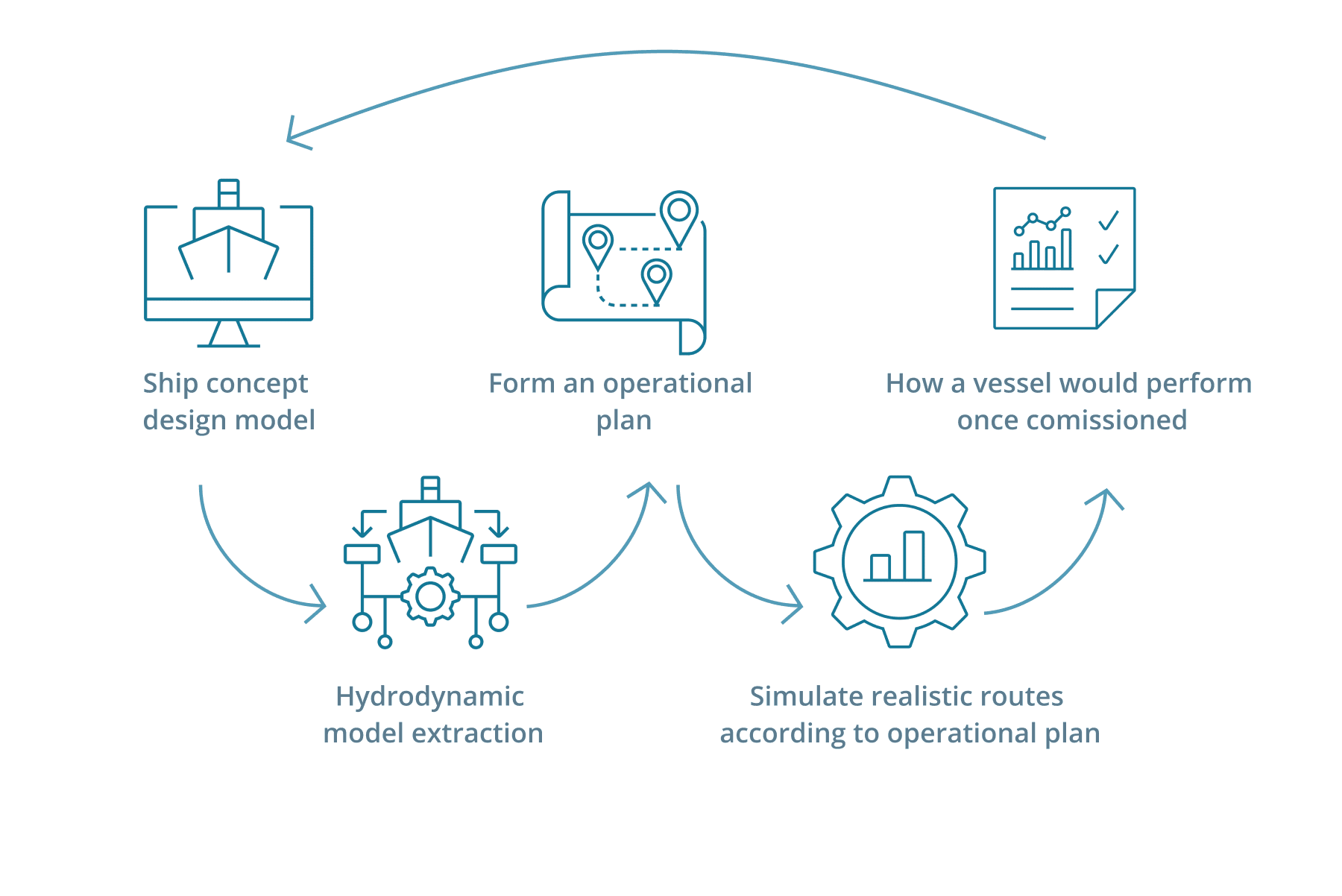

How does this work in practice? When data on similar vessels isn’t available, we can still model the behavior of a future ship by following three steps:

Step 1: Create a hydrodynamic model.

Based on the 3D model used to design the vessel, a hydrodynamic model captures how a specific ship will perform at various speeds and in different sea conditions.

Building a hydrodynamic model from scratch can be a momentous and time-consuming task, but there is no need to – instead, the key is to make the most of digital tools that already exist on the operational side. The NAPA Performance Model, which offers a baseline model for all existing vessel types and sizes worldwide, is a perfect framework for this analysis – which is then refined with data reflecting the new design’s unique characteristics.

Step 2: Determine an operational plan.

This outlines the areas where the vessel will be operated and the ports it will visit, but also the range of speeds considered and the loading conditions that it will experience.

This is easier for retrofitting projects, where we already have a detailed picture of a vessel’s operations. But for newbuilds, a lot of insight can be gained from AIS data. NAPA’s databases comprise AIS data from 60,000 vessels, covering several years, supported by algorithms to make sense of this data and filter it per vessel type and size, for example. In practice, this provides invaluable insight into how ships tend to be operated – in any given area and for any vessel type.

Step 3: Simulate realistic voyages.

Bringing the hydrodynamic model and the operational plan together, we can model the future ship’s performance on the specific routes where it will be operated.

NAPA Voyage Optimization is configured to do exactly that. The tool was created for weather routing, and it does so by simulating a ship’s behavior on multiple route variations to determine the optimal course and speed profile between two ports, anywhere in the world.

While its primary purpose is for operations, nothing stops us from using it to model theoretical voyages for vessel concepts that are still on the drawing board.

We can use historical nowcast weather data and statistical climatology data from the relevant sea areas and times of year to simulate the weather conditions and sea states the ship will operate in. By doing so, we can model the future ship’s speed ranges, engine loads, fuel consumption and greenhouse gas emissions in operation.

In addition to designing more energy-efficient ships, our operational simulation tools can be used to develop safer and more durable vessels. Ship designers can evaluate a future vessel’s seakeeping capabilities and assess structural load requirements for the realistic conditions and voyages the ship will navigate over its lifetime.

The best part for ship designers is that they can repeat all of this analysis on different design iterations to determine which option will be optimal to meet the owner’s unique operational needs.

Case study – Testing design iterations

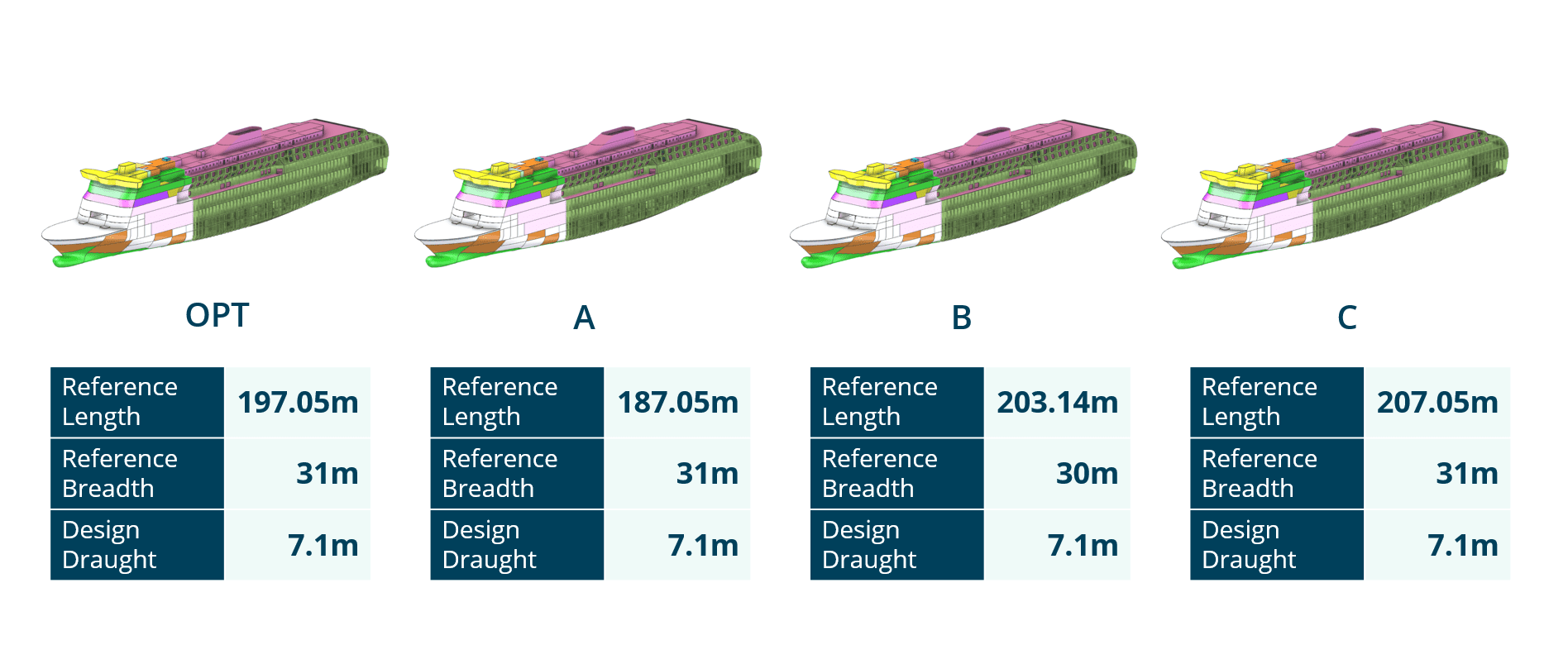

To illustrate what this looks like in practice, let’s take the example of a newbuild RoPax vessel serving the route between Stockholm, Mariehamn and Helsinki, in the Baltic Sea.

We started with a baseline vessel with a length of 197 meters, 31m breadth and 7.1m design draught. We then created three variations, each with different dimensions and configurations, while maintaining the displacement (or weight) constant.

The next step is to establish an operational plan, accounting for the routes between the three ports, speed limitations in the Swedish archipelago, and slower speeds for port entry. From this, we simulated 26 voyages – one every fortnight – covering the whole of 2023.

The result was a wealth of insight that could be actioned to improve the design. It revealed that the future ship will spend about 50% of its time sailing at full speed, 25% in port, with slow-speed operations making up the rest. This is valuable knowledge from a design perspective because it helps understand the levels of propulsion power that will be needed and select the right engine power and configuration to maximize its energy efficiency.

Simulating new fuels and energy sources

Taking this one step further, we could simulate future fuel consumption to compare the costs and emission reduction benefits of different fuel options for the specific vessel. Future EU ETS and FuelEU penalties can be included in the calculation, providing a comprehensive picture of fuel costs this decade and into the future. Such simulations can reveal sizable differences among design variations when new operating costs are taken into account, ultimately translating into substantial savings for the owner. The uncertainty of such analysis depends on the accuracy of predicted fuel prices and expected regulatory costs, but as the regulatory landscape and price projections become clearer, operational simulation tools will become even more powerful.

Thinking differently to future-proof ship designs

Why does this vision matter? Because decisions as critical as ship design choices must be based on data and evidence to enable the maritime industry to progress with confidence towards its decarbonized future.

This exercise demonstrates how, by thinking outside the box and making the most of simulation tools already at our disposal, we can provide clear answers to one of the most pressing questions for potential first-mover shipowners: Will my new vessel be safe, efficient, compliant, and—crucially—respond to my operational needs?

This comes as innovation in ship design is no longer a “nice to have”, but is becoming critical amid new environmental regulations, including EU ETS, FuelEU and the IMO’s GHG Strategy, which will all require energy-efficient designs and, eventually, transition to new fuels.

There are commercial benefits, too: we already see today that eco vessels are achieving better charter rates, with premiums reaching 10,000 USD per day or even higher for certain vessel types. But to encourage more owners to make the jump, we will need to demonstrate with solid data analysis how their investment is sound and how their assets will be future-proof and compliant throughout their lifetime, often exceeding two decades.

More broadly, this is also a testament to the power of operational data in supporting innovation in ship design. As the number of innovative vessels at sea grows, we have an opportunity to create new bridges between design and operational data. This will be critical to enable insights from real-life operations to be fed back into the design process and increase the performance of the future fleet. It will require owners and shipyards to cooperate on anonymized, secure data sharing, but it will be worth it. The maritime industry, people and the planet all stand to benefit.